Staying Clear Of Usual Risks in Business Boiler Option and Installation

When it comes to industrial central heating boiler option and setup, guaranteeing a smooth and efficient process is important. Think of running into unexpected concerns that could have been conveniently prevented. By understanding the subtleties of sizing, energy efficiency, maintenance, ventilation, and installation techniques, you pave the way for a successful procedure. Bear in mind, the devil remains in the information when it pertains to business boilers.

Key Takeaways

- Conduct complete heat evaluation before choosing the central heating boiler size.

- Prioritize high power effectiveness ratings for price savings.

- Comply with regular upkeep routines to stop breakdowns.

- Make sure correct air flow for risk-free and reliable operation.

- Guarantee appropriate installation by trained professionals to prevent dangers.

Incorrect Central Heating Boiler Sizing

When choosing an industrial central heating boiler, ensuring the correct size is important to effectiveness and efficiency. Proper heat exchanger sizing plays a pivotal function in the general functionality of the system. A well-fitted warm exchanger guarantees that warmth is moved effectively, taking full advantage of power effectiveness and reducing operational expenses.

Performance optimization goes to the heart of correct sizing, as an oversized boiler may lead to brief biking, where the central heating boiler activates and off regularly, throwing away power and creating unneeded deterioration. On the other hand, an undersized boiler battles to meet the home heating needs of the space, causing inefficient operation and possible pain for passengers.

To prevent these challenges, it's necessary to carry out a thorough assessment of the home heating requirements of the structure prior to picking a boiler. Consulting with a professional to execute a warmth lots computation can assist determine the appropriate dimension needed for efficient performance. By choosing the best size, you can make sure that your industrial central heating boiler operates successfully, effectively, and economically.

Overlooking Power Performance Ratings

Don't forget the significance of power efficiency rankings when choosing a commercial central heating boiler for your building. Making best use of effectiveness is essential for minimizing functional costs and ecological impact. When picking a boiler, look for high-efficiency versions that can provide optimal efficiency while making use of very little power. Energy efficiency ratings indicate just how properly the central heating boiler converts gas into warmth, so picking a very rated system is crucial to accomplishing efficiency excellence.

By opting for a boiler with a high energy effectiveness rating, you can assure that your building's home heating demands are fulfilled while maintaining utility bills in check. These efficient boilers not only assist in reducing energy intake but also add to a greener environment by decreasing carbon discharges. Efficiency excellence goes together with energy effectiveness, as a well-performing boiler can enhance overall heating system performance and longevity.

Focusing on power effectiveness rankings in your commercial central heating boiler selection process is a wise investment that can result in long-term financial savings and improved sustainability for your building. Ensure to take into consideration this aspect together with other technical specifications when making your choice.

Overlooking Upkeep Demands

Ignoring upkeep requirements for your business central heating boiler can bring about pricey repair services and potential breakdowns. To avoid these issues, it is essential to adhere to regular maintenance timetables. Adhering to manufacturer-recommended maintenance routines, such as looking for leaks, screening safety controls, and validating proper water levels, can help recognize and attend to minor concerns before they rise into major troubles.

Furthermore, familiarizing yourself with the boiler's repairing guides can assist in quickly fixing any kind of functional problems. Understanding typical indication, like unusual noises or changes in stress, and understanding just how to address them can conserve you time and money in the long run. By proactively keeping your central heating boiler and attending to any problems promptly, you can ensure its durability and peak efficiency.

Insufficient Air Flow Factors To Consider

Correct air flow is important for the safe and effective operation of your business central heating boiler. Ventilation design plays a basic function in guaranteeing that the boiler gets an ample supply of combustion air while additionally effectively getting rid of flue gases. Failure to consider air flow needs can result in poor combustion, decreased effectiveness, and safety risks.

When developing the air flow system for your commercial boiler, it is essential to precisely compute the air flow needs. Poor air movement can cause insufficient burning, resulting in the manufacturing of carbon monoxide gas, a colorless and odor-free gas that presents serious health risks.

To prevent such problems, speak with heating and cooling specialists to determine the suitable ventilation design for your specific boiler configuration. Factors such as the boiler's dimension, gas type, and place within the structure all influence the air movement needs. By ensuring appropriate air flow, you not only maximize the efficiency of your industrial central heating boiler however also guard the wellness of residents in the building.

Improper Installation Practices

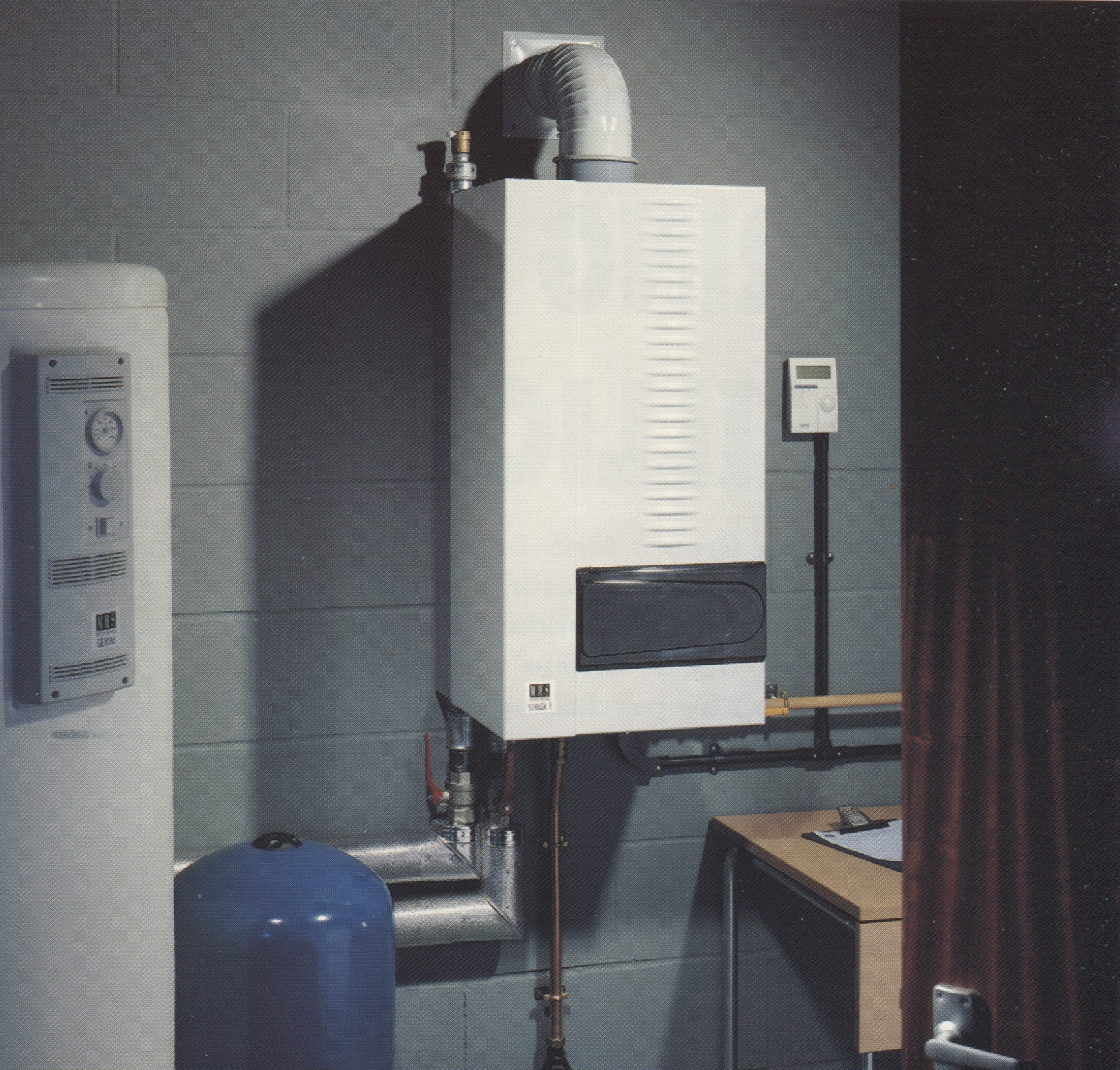

Warranty proper setup of your commercial central heating boiler to avoid potential security hazards and performance issues. Improper piping throughout installment can result in inadequacies and even system failures. Inaccurately sized or improperly linked pipes can create concerns such as lowered warmth outcome, leaks, and enhanced power intake. Ensure that the piping is done by specialists that comprehend the details demands of your boiler system.

One more typical pitfall is poor training throughout the installation procedure. It's crucial that the people responsible for mounting the central heating boiler have actually gotten correct training from the producer or various other professional resources. Without appropriate training, errors can easily occur, bring about malfunctions, safety and security threats, and lowered performance. Make certain that the installment group is experienced about the specific design being installed and complies with all suggested procedures.

Overlooking Safety Rules

You must see to it that your industrial central heating boiler setup follows safety codes to stop mishaps. Carrying out detailed danger assessments is crucial for recognizing potential hazards and carrying out preventive measures.

In addition, keeping up to day with regulatory evaluation requirements is important to preserve the security and effectiveness of your boiler system.

Safety Code Compliance

Disregarding security regulations when choosing and setting up industrial central heating boilers can lead to severe effects for your center and its residents. Safety and security code interpretation is necessary in assuring that your central heating boiler system fulfills all required policies to guarantee the security of your structure and its residents.

Compliance training plays a significant function in informing workers on the details safety codes and standards that must be complied with during the selection and installation process. Failure to comply with these laws can cause severe dangers, placing the safety of the center and people in jeopardy.

Therefore, it's vital to prioritize safety code conformity and give adequate training to avoid potential accidents and ensure a risk-free workplace for everyone involved.

Threat Analysis Procedures

To guarantee the safety and security of your facility and its occupants, performing extensive threat analyses is vital when choosing and installing commercial boilers. Executing risk administration strategies and following security procedures are important action in this procedure.

Begin by recognizing potential hazards related to central heating boiler installation and operation, such as leaks, stress issues, or poor air flow. Mitigation techniques ought to be established to address these dangers effectively. Routine risk analyses ought to be conducted to make sure ongoing security compliance and to prevent crashes or malfunctions.

Regulatory Examination Demands

When forgeting safety and security policies, failing to comply with governing examination demands can bring about serious effects for the proper functioning and upkeep of commercial central heating boilers. To stay clear of these risks, make sure to stay up to date with conformity updates and follow assessment timelines.

Here are some bottom lines to consider:

- Regular Inspections: Arrange routine inspections to make certain the central heating boiler fulfills all safety and security requirements.

- Documents: Maintain thorough documents of all examinations and maintenance tasks.

- Educating: Guarantee that personnel in charge of central heating boiler maintenance are trained on safety and security guidelines.

- Motivate Action: Address any type of problems determined throughout inspections quickly to keep a secure workplace.

Frequently Asked Inquiries

Can a Business Boiler Be Mounted Without Correct Air Flow?

You should never ever install an industrial boiler without appropriate air flow. Not complying with safety and security laws concerning ventilation can cause serious dangers.

Sufficient ventilation is important in ensuring the secure operation of a boiler and avoiding possible risks. Always focus on boiler system design to preserve a safe workplace and adhere to guidelines.

What Are the Repercussions of Neglecting Safety Laws Throughout Setup?

Ignoring safety regulations throughout setup of a commercial central heating boiler can result in significant consequences. Neglecting air flow needs may cause inadequate air high quality and potential health hazards. Safety protocols are crucial to prevent accidents and guarantee appropriate functioning.

Inadequate setup can also affect energy efficiency, resulting in higher operational prices. Focusing on safety and security and adhering to regulations is essential for an effective and efficient boiler installation procedure.

Exactly How Does Incorrect Boiler Sizing Effect Power Effectiveness?

Inappropriate sizing of your central heating boiler can have a major effect on power effectiveness. When your central heating boiler is too large, it will certainly cycle on and off regularly, losing energy.

Alternatively, if it's too little, it will certainly struggle to meet your structure's heating demands, resulting in raised power intake.

Guaranteeing the correct dimension for your central heating boiler is crucial in optimizing energy effectiveness and reducing functional expenses over time.

Can Maintenance Requirements Be Overlooked Without Affecting Performance?

Ignoring maintenance and air flow demands can have detrimental effects on the performance of your business central heating boiler.

Overlooking regular upkeep jobs like cleansing and evaluations can lead to decreased effectiveness and prospective failures.

Furthermore, neglecting ventilation demands can compromise the safety and security of your system and structure passengers.

Prioritizing these elements is important to ensure that your central heating boiler operates effectively and safely over time.

What Are the Dangers of Overlooking Power Effectiveness Ratings in an Industrial Boiler?

Overlooking power performance scores in a commercial boiler can lead to higher functional costs and a negative ecological impact. Forgeting this facet might lead to missed out on possibilities for long-term financial savings and suboptimal efficiency.

Conclusion

To summarize, by avoiding usual challenges in industrial boiler selection and installment, you can ensure peak efficiency, effectiveness, and safety.

Proper sizing, factor to consider of energy efficiency scores, adherence to maintenance requirements, air flow considerations, and installation techniques are all crucial for maximizing the longevity and efficiency of your business boiler system.

Don't overlook these essential elements to prevent costly mistakes and safeguard a well-functioning heating unit for your business area.